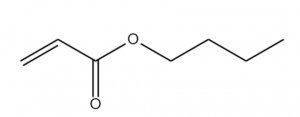

Butyl Acrylate (BA)

Butyl Acrylate (BA)

Nqe lus piav qhia:BA yog ib qho mos monomer uas muaj zog reactivity, uas tuaj yeem sib txuas, copolymerized thiab txuas nrog ntau yam nyuaj monomers los tsim emulsions, dej-soluble copolymers thiab lwm yam polymers, thiab tuaj yeem npaj cov yas thiab cross-linked polymers kom tau txais ntau yam khoom. nrog cov yam ntxwv sib txawv xws li viscosity, hardness, durability, iav hloov kub, thiab lwm yam.

Butyl acrylateyog ib qho tseem ceeb nruab nrab nrog kev siv siab heev.Nws yog siv heev Extensive.Tshwj xeeb tshaj yog raws li MMA thiab MBS resin modifiers nyiam ntau xim txawv teb chaws.

Yam ntxwv:

1. Cov dej tsis zoo

2. Tsawg kub hloov tau

3. Cov huab cua tiv taus zoo heev

4. Kev tiv thaiv tshav ntuj zoo.

Daim ntawv thov:

1. Butyl acrylate feem ntau yog siv los ua polymer monomers rau fibers, roj hmab thiab yas.

2. Kev lag luam organic yog siv rau hauv kev tsim cov nplaum, emulsifiers thiab ua intermediates hauv organic synthesis.

3. Kev lag luam ntawv yog siv rau hauv kev tsim cov ntawv ntxiv dag zog.

4. Kev lag luam txheej yog siv rau hauv kev tsim cov acrylic coatings.

5. Polymerizable monomers, siv nyob rau hauv mos polymers, ua si lub luag hauj lwm hauv plasticizing hauv copolymer.Ntau yam resins rau kev npaj cov txheej, textiles, papermaking, tawv, siv cov nplaum thiab lwm yam lag luam.

General lus qhia:Cov tshuaj lom ntawm cov khoom no zoo ib yam li methyl acrylate.Qhov ncauj LD50 ntawm nas yog 3730 mg / kg.Irritating rau qhov muag thiab tawv nqaij.Qhov siab tshaj plaws tso cai yog 10-5.Qhov chaw ua haujlwm yuav tsum muaj qhov cua zoo.Cov neeg ua haujlwm yuav tsum hnav cov iav tiv thaiv.

Pob:180kg / nruas

Kev thauj mus los thiab khaws cia:

1. Khaws rau hauv qhov chaw txias, cua txias.Khaws kom deb ntawm qhov hluav taws kub thiab cua sov.Lub tsev qiv ntawv kub yuav tsum tsis pub tshaj 37 ℃.

2. Lub ntim yuav tsum tau muab kaw thiab tsis txhob sib cuag nrog huab cua.

3. Nws yuav tsum tau muab cais los ntawm oxidants, acids thiab alkalis, thiab yuav tsum tsis txhob sib tov.

4. Nws yuav tsum tsis txhob muab khaws cia rau hauv qhov ntau lossis khaws cia rau lub sijhawm ntev.Siv cov khoom tawg-pov thawj teeb pom kev zoo thiab qhov cua qhov cua.

5. Txwv tsis pub siv cov cuab yeej siv tshuab thiab cov cuab yeej uas ua rau muaj qhov tawg.

6. Lub chaw cia khoom yuav tsum tau nruab nrog cov khoom siv kho mob thaum muaj xwm txheej ceev thiab cov khoom ntim khoom tsim nyog.

![3-(1-(Dimethylamino)ethyl]phenol](http://cdn.globalso.com/jindunchem-med/image271-300x300.png)