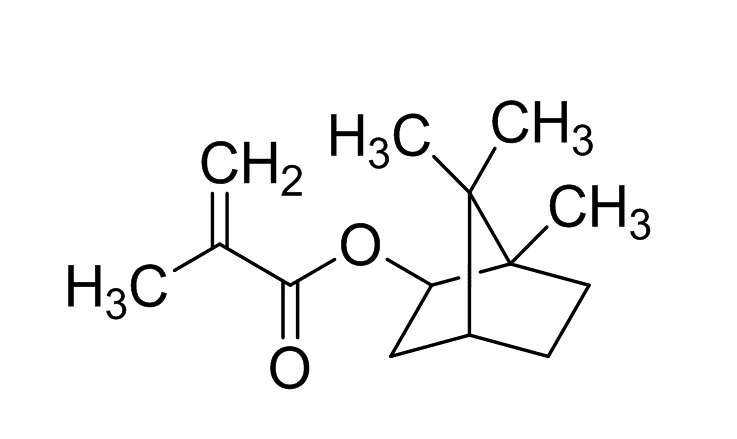

Isobornyl methcrylate (IBOMA)

Isobornyl methcrylate (IBOMA)

Nqe lus piav qhia:IBOA, vim nws cov qauv tshwj xeeb thiab cov khoom, yog nyiam cov neeg nyiam thiab mloog hauv kev tshawb fawb thiab daim ntawv thov ua cov acrylic monomers tshiab hauv xyoo tas los no.IBOA tuaj yeem siv los tsim cov khoom siv polymer ua haujlwm tau zoo ntxiv kom ua tau raws li cov thev naus laus zis niaj hnub thiab ib puag ncig.Nws muaj kev cia siab rau daim ntawv thov zoo Nyob rau hauv cov khoom siv high-solids coatings, automotive coatings, light-curing coatings, optical coatings, the modified powder coatings, etc.

Yam ntxwv:

1.Excellent UV tsis kam, dej tsis kam thiab tshuaj tiv thaiv;

2.Low viscosity, Txhim kho kev sib raug zoo nrog lwm cov resins thiab cov kuab tshuaj;

3.High-boiling, tsawg-volatile;

4.High reactivity;

5.High hardness, tsawg shrinkage.

Daim ntawv thov:

1.IBOA ua cov polymers muaj cov khoom zoo heev, xws li siab gloss, txawv ntawm cov duab, abrasion kuj thiab huab cua tsis kam, tshuaj tiv thaiv.Siv rau high-qib xim formulations;

2.Siv rau cov ntawv kub-resistant organic ntawv, fiber ntau, nplaum, luam ntawv inks uas muaj reagent, hloov hmoov txheej, ntxuav coatings, siab solids low viscosity coatings;Reactive diluent, hloov kho resin monomer kom toughness, thiab txhim kho cov dispersibility ntawm resin rau cov xim;

3.Nyob rau hauv cov txheej txheem acrylic resin, tuaj yeem txo cov viscosity ntawm cov tshuaj polymer zoo (feem ntau cov nyhuv yuav pom tseeb dua hauv tsib feem pua rau kaum feem pua los yog li ntawd);

4.IBOA haum rau kev tsim cov khoom siv siab Tg thermoplastic acrylic resin, uas cov khoom muaj siab hardness, siab cawv tsis kam, kub tsis kam, zoo elasticity adhesion thiab ya raws, huab cua tsis kam.

5.IBOA yog ib qho tshiab acrylate monomer nrog cov qauv tshwj xeeb, siv cov txheej txheej nyias nyias ntawm cov yas mos, xws li PET, PE, PP, thiab lwm yam. Thiab cov txheej txheem zoo nkauj ntawm PE, PP, PC thiab lwm yam khoom yas .

General lus qhia:Hluav taws kub!Polymerization tuaj yeem pib los ntawm kev sib kis nrog peroxides, azo compounds, hnyav hlau ions, tert.Amines, S compounds.Polymerization kuj yog induced los ntawm lub teeb.Atomospheric oxygen saturation nyob rau hauv lub monomer yog tsim nyog rau stability.Cia kub yuav tsum tsis pub tshaj 35 ℃.

Kev thauj mus los thiab khaws cia:

1.Tsis txhob ci los nag thiab kub kub hauv kev thauj mus los;

2. Khaws cov khoom nyob rau hauv txias, shady thiab ventilated tej yam kev mob, kom deb ntawm hluav taws kub;

3.12 lub hlis txij li hnub xa khoom ntawm qhov kub siab tshaj plaws ntawm 30 ℃.

![6-tetra-O-acteyl-1-C-[4-chloro-3-[[4-[[(3S)-tetrahydrofu-ran-3-yl]oxy]phenyl]](http://cdn.globalso.com/jindunchem-med/0ecf55f0-300x300.jpg)